Downtown Houston has been fortunate to benefit from a transformation over the last couple of decades. Beautiful green spaces, luxury high-rises and hotels, restaurants, and updated arts and entertainment facilities are home to impressive art installations, farmers markets, major professional sporting events, and more. On the flip side of this, Houston’s central business district has seen a steep decline in commercial occupancy, struggling to bounce back to pre-COVID levels.

Houston is not alone in experiencing this situation. Nationwide, commercial vacancies are becoming increasingly noteworthy as the gap between residential rental rates and stagnant wages widens. Low-income earners, folks making between $20,000 and $30,000 annually (typically minimum wage employees, students and seniors living on Social Security), have been joining the ranks of the unhoused at an alarming rate due to the scarcity of affordable housing. Armchair economists and the like have been arguing for years that cities should repurpose these untapped resources into an opportunity to create dignified affordable housing that would keep those at risk off the streets and close to public transit options.

Pew Charitable Trust, along with international architectural firm Gensler, recently released their findings from a study on the subject — with Houston being one of two markets studied. The “Flexible Co-Living Housing Feasibility Study” found that converting Houston’s empty office buildings to communities of micro-apartments is, well, feasible.

“In the current climate of high construction costs, interest rates, building expenses, and rising rents, this project looks at the conventional office-to-residential conversion in a different way by leveraging the existing building infrastructure to reduce costs on a per unit basis,” Brooks Howell, principal architect at Gensler, tells CultureMap. “The result is a new housing typology, a co-living concept, that can provide affordable housing to the large and growing number of lower income single-person households in an urban context.”

The numbers

HUD reported that in 2024 homelessness was at an all-time high of 770,000 persons, up a staggering 18 percent from the prior year. Houston is on the low end of the national average, with a reported 3,270 homeless persons (4/10,000 Houstonians). CoStar data shows that Houston’s central business district contains 88 office buildings of over 50,000 square feet, 19 of which show reported vacancy rates of over 30 percent. As of November 2024, the median rent in Houston for an apartment was $1,297. The proposed rental rate for a furnished micro-apartment in a converted office building in downtown Houston is $700 — all inclusive, with zero move-in costs, as the units are fully furnished.

“The U.S. has a housing shortage of 4-7 million homes, which has driven rents to an all-time high and made it hard to save to buy a home,” Alex Horowitz, a project director for Pew Charitable Trust and a co-author of the study, adds. “Houston has one of the highest office vacancy rates in the U.S., but office layouts often don't work well for apartment conversions and carry high costs. This study finds that converting offices to dorm-style housing is cost-effective and can enable low rents — about $700 per month to live downtown. That could make a real difference for people struggling with high housing costs while revitalizing downtown.”

Co-living explained

Co-living is hardly a new concept. “Single room occupancy” dwellings, or SROs, were extremely common until about 1950. It’s worth noting that during the height of its popularity, homelessness was rare. The co-living model allows for a private furnished space, while bathrooms, kitchens, and laundry are shared facilities — much like a college dormitory. With 40 percent of renters being single occupants, this model promotes socialization and community, something that has been trending downward since the pandemic.

Wesley LeBlanc, principal analytics director for Gensler Chicago, adds that this elevated dorm situation is a “jumping off point for a number of models,” noting that there are six variations from the one in the study. LeBlanc encourages people to “Think beyond the conventional. A whole world of housing solutions come out of this.”

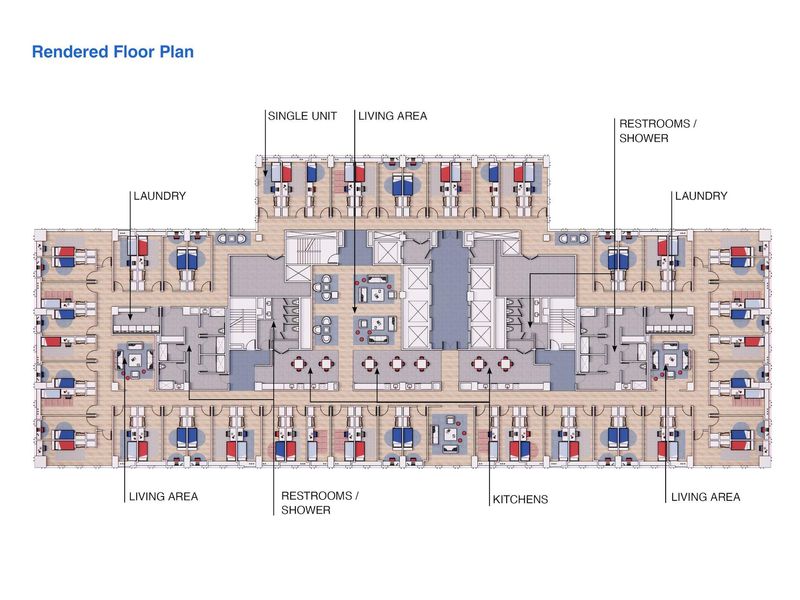

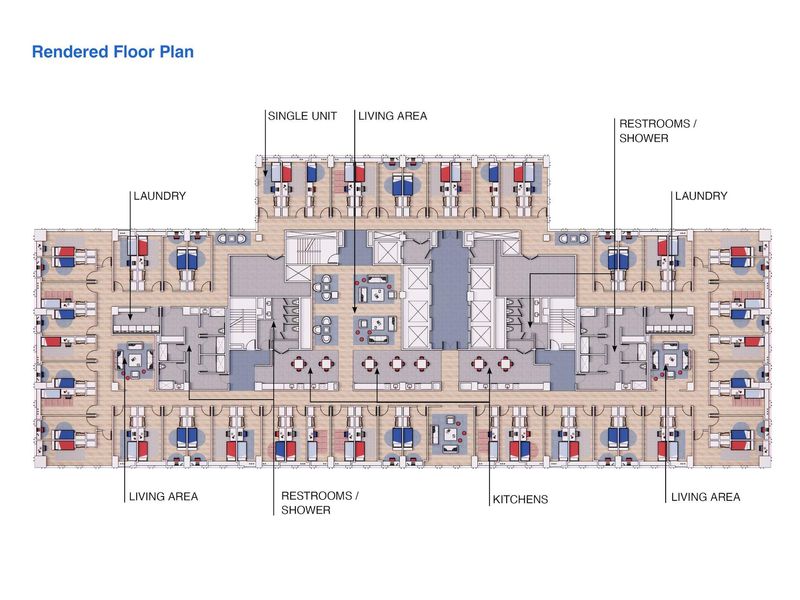

Individual rooms share amenities such as larger living rooms, bathrooms, and kitchens.Courtesy of Gensler

Individual rooms share amenities such as larger living rooms, bathrooms, and kitchens.Courtesy of Gensler

What to expect in a typical converted building

The Pew/Gensler report proposes a prototypical building standard of 24 floors, 19 of which are residential, with 60 micro-apartments per floor, or 1,140 residential units per building. Each floor would offer six shared kitchen areas, five larger shared living spaces, two smaller shared living spaces tucked into interior hallways, two central shower areas with five private shower rooms each. Two shower rooms would include toilets and sinks, plus two additional toilet rooms with four toilets and two sinks. The total comes to 10 showers, 12 toilets, and 14 sinks per floor. Two laundry rooms, each with three washers and dryers, would also be available per floor.

The high cost of converting office buildings into fully plumbed, individual studio apartments can be cost prohibitive, leading a pragmatic Howell to ask: “What if we didn’t demo everything?” The utilization of existing centralized plumbing on each floor saves an average of 25-35 percent in construction costs that would arise from running new plumbing to each unit.

The ground floor would consist of a main lobby, management office, and 10,000 square feet of retail space. Floors two through four would be reserved for parking, while the fifth floor would offer 10,000 square feet of Class B office space as well as amenities like the gym.

While subsidies will be required for the conversion, the same will not be true once the development is out of the construction phase. The co-living model is projected to cost around one-third of the cost of converting an office building to individual studio apartments or constructing new affordable housing.

An illustration of what a bedroom would look like.Courtesy of Gensler

An illustration of what a bedroom would look like.Courtesy of GenslerMicro-apartments details

Each individual unit is designed to be 151 square feet, approximately the size of a modest hotel room. Furnishings include one extra-long twin bed (bedding included), a desk, chair, nightstand, standard-depth half-sized fridge, storage shelf, and cabinet. Units would have solid-core wooden doors and appropriate sound insulation — all for a tidy $700 per month.

Pricing has been a key factor in determining this configuration for affordable, urban housing. “Lowering the cost of housing to manageable levels enables residents to spend more on the other financial needs of their lives, which has broad implications for quality of life and well being,” LeBlanc explains.

---

This story originally appeared on our sister site, CultureMap.com.

Individual rooms share amenities such as larger living rooms, bathrooms, and kitchens.Courtesy of Gensler

Individual rooms share amenities such as larger living rooms, bathrooms, and kitchens.Courtesy of Gensler An illustration of what a bedroom would look like.Courtesy of Gensler

An illustration of what a bedroom would look like.Courtesy of Gensler The BoxPrefab houses are created offsite and then set up on the property. Photo courtesy of BoxPrefab

The BoxPrefab houses are created offsite and then set up on the property. Photo courtesy of BoxPrefab

Apple doubles down on Houston with new production facility, training centerPhoto courtesy Apple.

Apple doubles down on Houston with new production facility, training centerPhoto courtesy Apple.